We know our way around international standards and are certified according to UL 508A.

From prototypes to custom-made products to large-series productions – we develop and produce all our controls in-house.

We are the specialists at your side for trusted, bespoke and intelligent controls for material lifts and conveyor systems.

From initial consultation to engineering to control engineering to installation and commissioning – we offer everything from a single source.

For us to offer you the best solution, we need to understand exactly what your needs and wishes are. These then have to be brought into line with the mandatory legal and in-country regulations. We record and document your entire project as a matter of course. Feasibility studies and safety assessments make up just as much a part of our consulting services, as do training courses. We know the pitfalls of international shipping inside and out and make sure that your goods reach their destination safely and intact.

We analyze, calculate and certify the performance level of the all safety-related parts of your control system

We verify the feasibility of your specifications for new systems or retrofits, taking into account all national and international regulations

We can demonstrate extensive expertise and knowledge of standards (ISO, ANSI, EN, UL, CSA), type testing & quality assurance

We deliver packaging solutions developed in-house to match the shipping method; close cooperation with local partners, global network

We log and document your entire project for end-to-end transparency

We offer advice on and run specific technical training courses for our end customers' employees

Our long-term experience in a variety of industries means that we can offer you perfect solutions for your individual specifications. To achieve this, we either use our own controls or work with controls from established suppliers like Siemens, Allen Bradley, Omron or SICK. We verify where optimization potentials exist and offer you appropriate alternatives. We advise you on the selection of suitable components and also develop plug & play solutions for larger production volumes. We create individual operating concepts ranging from simple push buttons to HMI panels to machine-to-machine communication.

We produce everything from prototypes to one-off products to large series internally at our two facilities in Kleinandelfingen (CH) and Ohio (USA). This allows us to act with agility and react flexibly at all times. We master complex national and international standards and are UL-certified (UL 508A). This make the process of exporting much easier, secure and more efficient. Our engineering team supports and guides our productions directly and very closely.

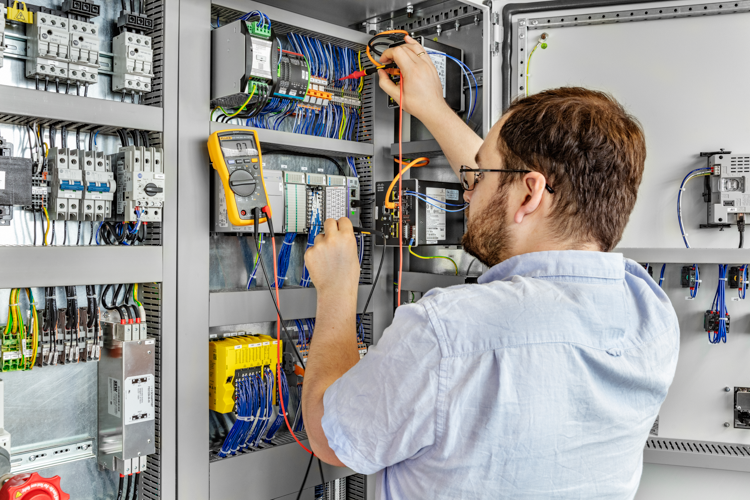

This allows us to integrate all types of interface fully. All the electronic components we develop we also manufacture in-house, and then assemble in the control cabinet and program. We also offer to manufacture cable sets, which we then produce entirely to your specifications. And finally, we set up and assemble all the components and put them through their paces so that nothing stands in the way of problem-free installation and commissioning.

The electrical installation includes the planning and assembly of all cable ducts and tubes incl. the subsequent cabling and wiring of all components ranging from the sensor/actuator to the control cabinet. If you have your own electrician or fitter, our supervisors will be happy to help them and connect the already laid cables to the control cabinet. Installation is complete and commissioning can start when the main switch on the control cabinet is successfully switched on.

Commissioning is carried out by our software engineers. Safety is our utmost priority at all times. For this reason, we check and log every sensor, actuator and interface meticulously. After the overall system test, training of the customer and on the system follows. Once all the components and functions have been approved, we hand over the turnkey product to you.

Downtimes costs money and prolongs your delivery times unnecessarily. You can rely on us to react quickly to any problems and give top priority to troubleshooting. We have spare parts available quickly and sustainably. These include emergency power supplies, batteries and safety devices, including light grids, but also individual cables, printed circuit boards and fuses. And we are ready and waiting if your need repairs done to your control or software updates and maintenance.

When it comes to retrofitting, we modernize existing systems, replace worn-out controls or extend them by adding our own electronic components. All individually tailored to your needs.